TL;DR :

- The blog is aimed at engineering students, manufacturing workers, teachers, training schools, and industries that want to develop high-level manufacturing competencies aligned with smart factory and Industry 4.0 demands through practical MES learning.

- Manufacturing Execution Systems (MES) are critical in modern manufacturing because they bridge the gap between enterprise planning and real-time shop-floor operations, enabling greater visibility, control, quality, and productivity.

- MES Training System offers real-life, simulation-supported learning programs that mediate between theoretical understanding and actual manufacturing implementation without exposing learners to the risks associated with live production systems.

- MES Training System enables the acquisition of such advanced skills as the management of digital production, IT-OT integration, making decisions based on data, quality control, traceability, and continuous improvement.

- As India has become a global manufacturing center, MES trainer manufacturers in India will play a crucial role in assisting in the development of skills, educating and providing education relevant to the industry, upskilling, and manufacturing competitiveness nationally.

Digitalization, automation, and data-driven decision-making are rapidly transforming manufacturing. The development of smart factories, cyber-physical systems and connected production environments has transformed the way products are designed, created, tracked and delivered. Traditional manufacturing skills alone are no longer sufficient in this fast-changing environment. The industries have turned to professionals who are capable of controlling, analyzing, and optimizing digitally enabled production systems.

At the center of this transformation is the Manufacturing Execution System (MES), which serves as a fundamental layer between enterprise planning systems and real-time shop-floor operations. Although the process of MES implementation in industries is gaining significant momentum, there is one major issue: it lacks the skilled workforce that is knowledgeable not only about MES concepts on paper, but also practically.

It is at this juncture that MES training comes in. MES Training System offers structured practical learning settings that recreate actual manufacturing operations to enable students and professionals to acquire practical exposure to contemporary manufacturing execution systems. As India sets itself up as the manufacturing center of the world, there has been a sharp increase in the demand for high-end manufacturing skills which has made all the MES training manufacturers in India even more relevant to the national skill development framework.

Related Blogs:

- How MES Laboratory Training Improves Practical Manufacturing Skills

- Transforming Labs with Workbenches: Bringing Industrial Discipline to Education

- Developing Industry-Ready AI Skills Through Industry-Aligned Training

Understanding MES and Its Role in Modern Manufacturing

A Manufacturing Execution System is a software-based solution that is used in real-time management, monitoring and control of manufacturing activities. It is the backbone of a smart factory, and it guarantees the smooth communication between the planning systems like ERP and the physical production process on the shop floor.

MES generally deals with tasks that include:

- Production scheduling and dispatching

- Real-time machine and process monitoring

- quality management and tracking of inspection

- Traceability of materials and genealogy

- Analysis of performance and OEE calculation

In contrast to the conventional production management systems where people use manual reporting and slow data, MES allows seeing the manufacturing performance immediately. This real-time understanding can enable manufacturers to cut downtime, better quality, productive operations and act swiftly upon disruption in operations.

Nonetheless, MES implementation and management needs a distinctive set of manufacturing domain expertise and IT expertise, data analytics proficiency and systems thinking. This interdisciplinary necessity implies the necessity of specialized training resources that would be able to equip the learners with the skills that would help them to cope with the real-word MES settings.

What Is an MES Training System?

An MES training system is a learning system used to teach how modern factories are managed using computer software called a Manufacturing Execution System (MES). Instead of only reading theory, students can practice how production is planned, how machines are monitored, how quality is checked, and how factory data is analyzed, all in a safe training setup. It usually includes MES software, simulated factory processes, and guided exercises that show how real manufacturing works step by step. In simple words, an MES training system is like a “practice factory on a computer” that helps learners understand and build skills for smart manufacturing and Industry 4.0 jobs.

How MES Training System Enable Advanced Manufacturing Skill Development

1. Hands-On Learning Through Realistic Simulations

The MES trainers expose trainees to the real-life manufacturing situation. Trainees are exposed to production schedules, machine states, quality alerts, and performance indicators, having a personal experience of the management of manufacturing operations on a digital level.

2. Integration of IT and Operational Technology (OT)

The current manufacturing requires the professionals who are aware of IT systems as well as of the physical production processes. MES trainers introduce learners to this integration through linking digital processes with simulated shop-floor processes.

3. Development of Analytical and Decision-Making Skills

MES produces enormous production volumes of data. Learners are also analyzing KPIs like OEE, cycle time, defect rates, and causes of downtime through trainers. This is a data-driven environment that promotes thinking and making decisions.

4. Understanding Production Planning and Control

The MES Training System assists learners to know how production plans are implemented at the shop-floor level. This training system looks at how work orders are assigned, how to allocate resources, and how to monitor the production progress in real time.

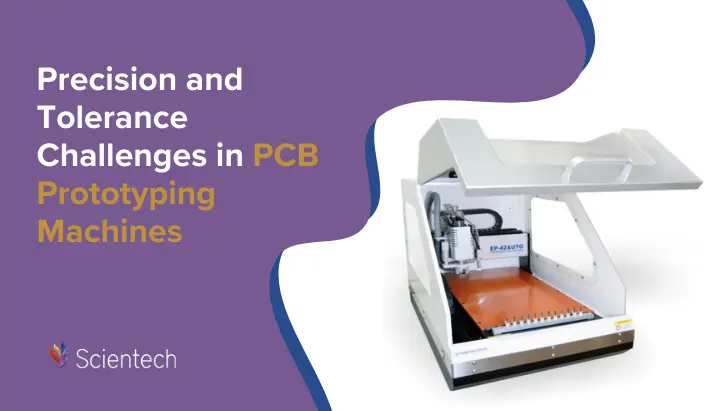

5. Exposure to Quality and Traceability Systems

One key element in modern manufacturing, particularly in regulated business, is quality management and traceability. The MES Training System will replicate quality inspection, defect tracking, and genealogy and they allow learners to get a feel of the compliance and quality assurance processes.

Advanced Manufacturing Skill Development

Advanced manufacturing skill development focuses on building technical and digital capabilities to work with highly technological modern manufacturing systems. With the technologies of smart factories and data-driven practices in industries, practitioners cannot afford to remain in the manual processes anymore without knowing what is produced in real time, how the system is integrated, and how to analyze its performance.

These are digital production management, data-driven decision-making, quality and traceability control, IT-shop-floor integration, and the continuous practice of improvement. MES training system facilitates this skill acquisition by providing practical learning experiences to learners in the simulated manufacturing environments, where learners can acquire practical skills without the risk of production.

Through its ability to facilitate the experiential learning process in line with actual industrial processes, MES training system assists in preparing a workforce that is ready to work in the future, especially in the rapidly expanding manufacturing platforms such as India.

Key Features of an Effective MES Training System

An excellent MES training system integrates various functional modules which indicate actual industrial MES implementation. These typically includes:

- Production Management Module

Handles work orders, routing, and production tracking. - Quality Management Module

Supports inspection planning, defect logging, and corrective actions. - Performance Monitoring Module

Visualizes KPIs, OEE, downtime, and throughput. - Traceability Module

Tracks materials, components, and finished goods across production stages. - User Role Management

Simulates different organizational roles and responsibilities.

A reputable MES vendor in India will make sure that these capabilities are user-configurable to meet education curriculum and industry needs.

Role of MES Training System Manufacturer India in Industrial Transformation

The manufacturing industry in India is developing at a high pace in terms of automotive, electronic, pharmaceutical, food processing, and heavy engineering. The nation needs to have a talented pool of workforce to manage this growth and this workforce should have expertise in digital manufacturing systems.

MES training system manufacturers in India play a strategic role because they:

- Plann how the trainers would be designed to meet the standards of manufacturing in India.

- Provid economical solutions that are viable in learning institutions.

- Allow for faculty training and supporting curriculum integration.

- Support localization and technical support.

The Indian MES Training System manufacturers work together with academia, industry, and government initiatives, which makes them directly responsible for national competitiveness in manufacturing.

Benefits of MES Training System for Learners and Organizations

For learners, MES Training System goes a long way to enhance employability and job readiness by offering practical exposure of smart manufacturing systems and real-time production management. This system, created by a trusted MES training system manufacturer in India, helps learners become familiar with real industrial processes, MES features, and data-driven decision-making procedures, enabling academic learning to be easily applied to industry work.

For educational institutions, MES Training System facilitates curriculum enhancement to align with industry demands and improve placement outcomes by ensuring that practical, MES-based training is incorporated into engineering and technical programs. Collaboration with a qualified MES training system manufacturer in India also helps institutions strengthen industry relationships and stay aligned with evolving manufacturing technologies.

For industries, MES training system save time on training and onboarding since teams will have the same level of skills on MES. Resolutions offered by a reliable MES training system manufacturer India enable the organization to train its employees in a simulation environment, which reduces the risks of operation, while maintaining productivity and system reliability.

Conclusion

Machinery and software alone are not enough for advanced manufacturing; skilled professionals are required to operate complex, data-driven production environments. MES Training System can satisfy this requirement by offering practical training which is industry-specific and which bridges the gap between education and actual manufacturing.

Since India is increasingly becoming a global manufacturing hub, the role played by all manufacturers of MES Training System India will be very vital. With MES Training System facilitating the possibility of practical MES education and workforce upskilling, it is not only training tools, but a means of industrial growth, innovation and competitiveness.

Making the steps towards smart manufacturing and Industry 4.0, MES trainers are one of the key pillars in the development of a future-oriented manufacturing workforce.

FAQs

An MES Training System is a training system that helps learners understand how manufacturing operations are managed using a Manufacturing Execution System through practical, simulated factory scenarios.

MES Training System can be used by students, working professionals, training institutes, and manufacturing companies to learn and improve smart manufacturing skills.

MES Training System provide hands-on learning without using live production systems, making it easier and safer to understand real manufacturing workflows and digital operations.

By working with real-time production data and MES tools, learners gain practical experience that improves their confidence, skills, and employability in manufacturing roles.

An MES trainer manufacturer India offers cost-effective, industry-relevant training solutions that are aligned with Indian manufacturing needs and skill development programs.