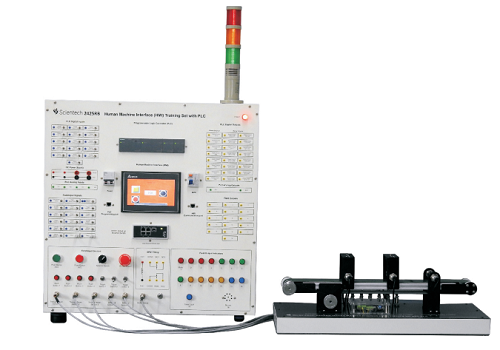

Scientech 2475 Multi Function Process WorkBench is a complete setup to measure process through two point

(ON/OFF) and three point (PID) controller. It is an Industrial Process plant with four processes Temperature ,

Liquid level, Pressure and Flow which we can measure through an Ethernet based Data Acquisition System whichhas 24 bit ADC and digital input/output. Scientech 2475 also gives us the exposure to the industrial components like Level Transmitter, Temperature Transmitter, Pressure Transmitter, Wheel Flow Transmitter, Rotameter, DAQ, PID controller and Temperature Sensor like RTD and Thermocouple. User can learn how to calibrate, install, operate and tune the instruments for controlling the process. All electrical components are connected to the control panel to allow students to measure signals and connect the devices in wide variety of control configuration including open loop (manual control) and close loop (PID control, ON/OFF control).

Scientech 2475 also has versatile software through which we can measure it from any PC which is in the local area network, software has features like logging of the process data, live and store Graph which can be printed when needed, alarm can be set for different points, animated real time view of complete process, easy IP configuration.

Features

• Temperature, Flow, Level, and Pressure Measurement

• Use of Industrial Process Control elements like Capacitive Level Transmitter, Temperature Transmitter,

Flow Transmitter , Pressure Transmitter, RTD and K Type Thermocouple Sensor, Rotameter and PID Controller , Solenoid Valve

• M.S Powder Coated Electrical Control Panel contain Start , Stop , Pump, Solenoid Valve , Stirrer button ,

Indicators for Pump, Heater, Stirrer, Solenoid Valve, Audio Indicator, Visual Indicator , Ammeter

• Real-time Ethernet based DAQ interface with ADC & Digital input/output

• Process Loop Tuning & Stable Process

• Process Control loops

• User Friendly Software

• Transducer/Transmitter Calibration

• Piping and instrumentation diagram

• Leak proof Safety measures, sturdy piping

• Enhanced Electrical Safety considerations

• Heat Transfer concepts

• Built-In Instrumentation

• SS Sump tank for inlet and outlet of water

• Robust construction

• Platform with Caster wheel arrangement for ease in movement